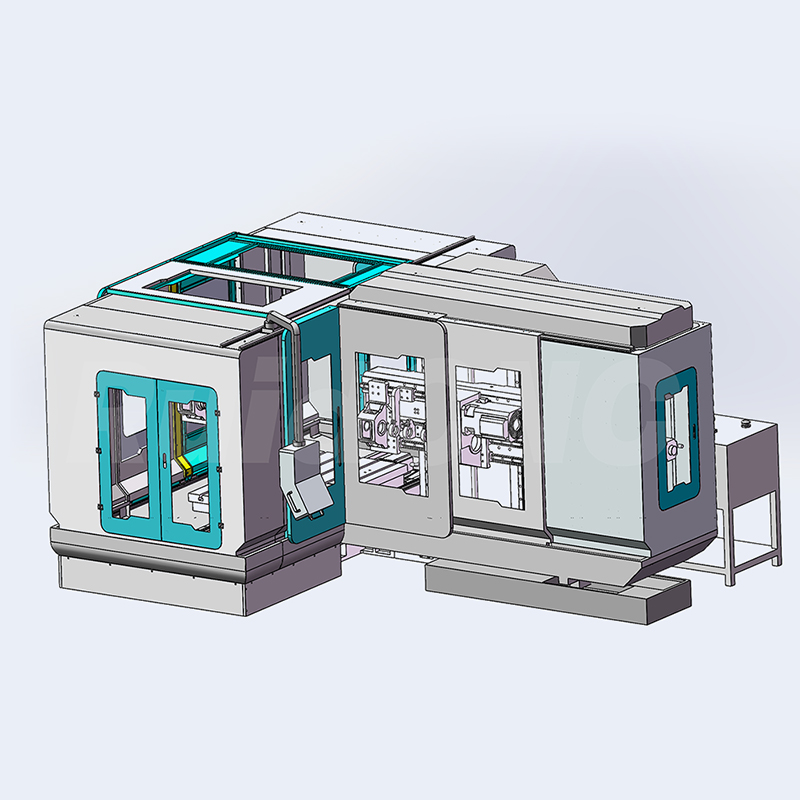

Product Introduction

The size and processing range of the working table on Shuangli ZJF customized CNC deep hole drilling machine can be customized according to user’s demand, proving the most appropriate solutions. As a special machine tool for deep hole processing, capacity and accuracy will be greatly improved, the diameter range: 3-35 mm, drilling depth: 200-2000 mm.

Performance parameter:

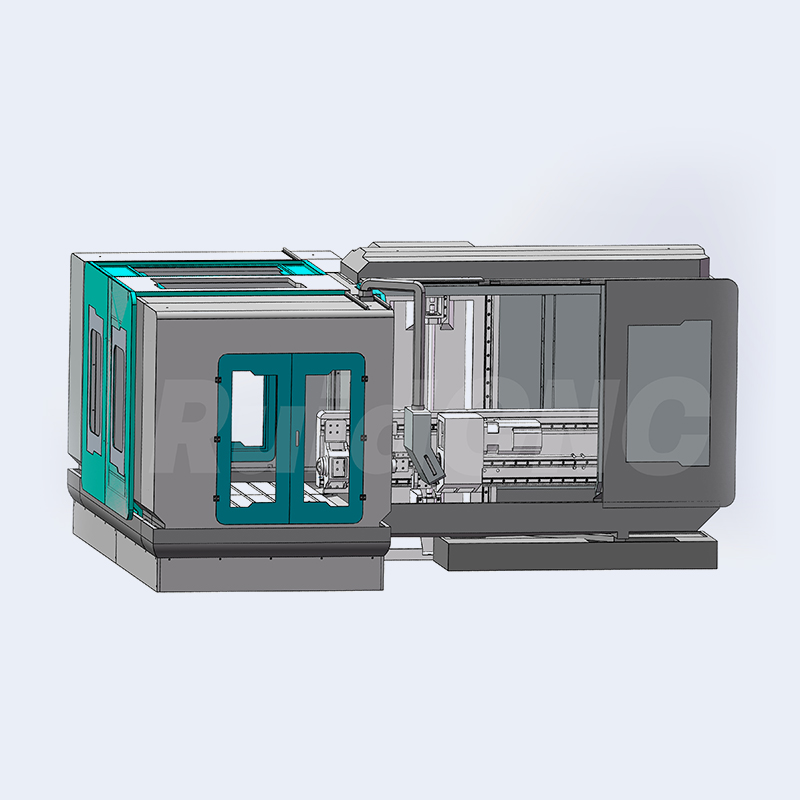

Single coordinate CNC deep hole drilling is compatible for single hole processing. V type iron clamping is recommended.

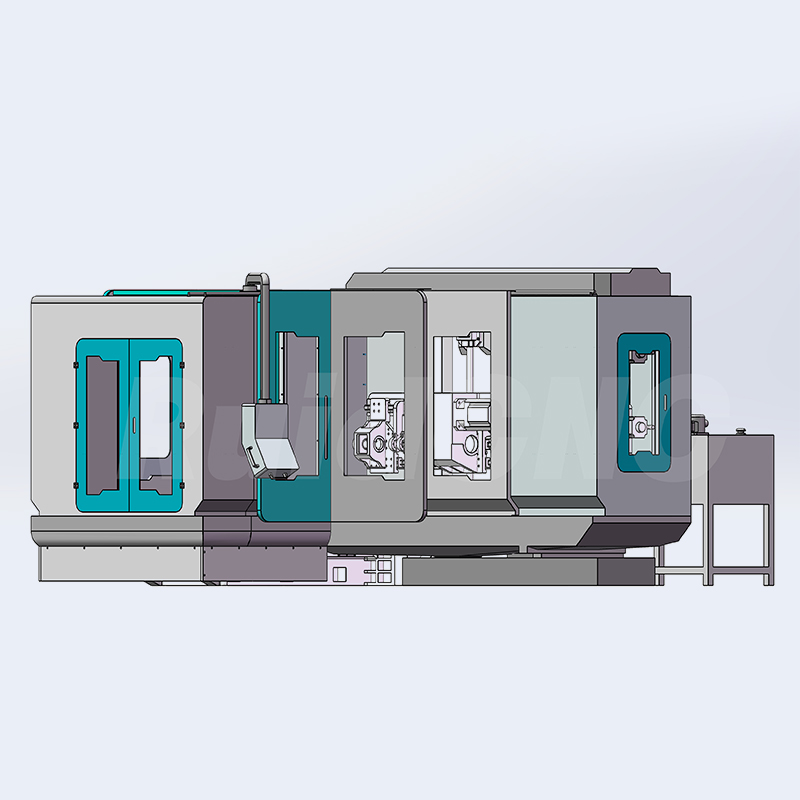

The depth of two coordinates CNC deep hole drilling is of 1500mm, and the worktable can be moved horizontally, which is suitable for plenty of horizontal hole processing. Range of application: circuit boards, cooling plate etc.

Reviews

There are no reviews yet.