FEATURE

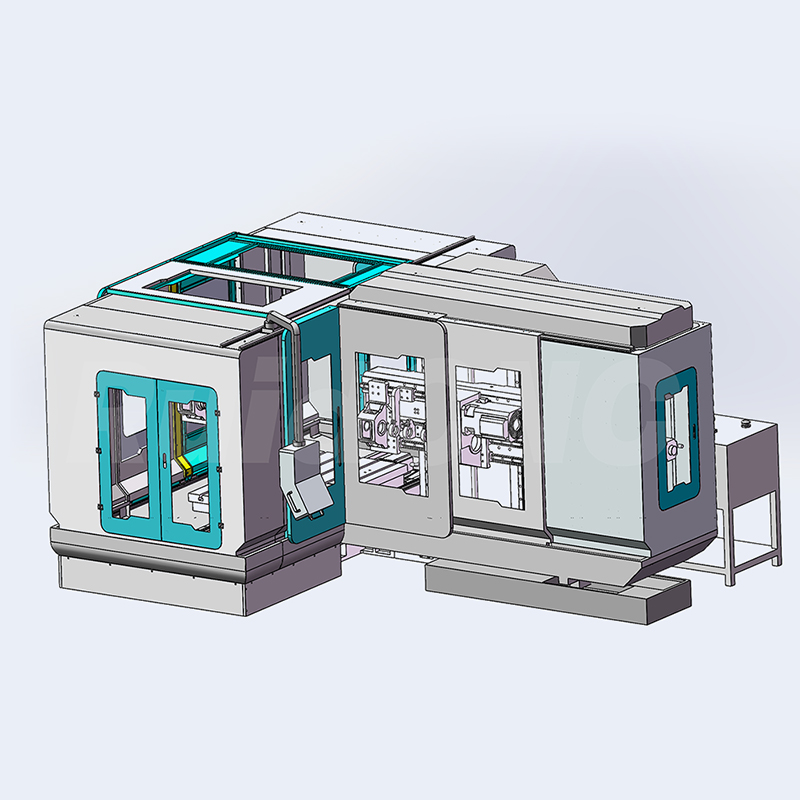

1.Three coordinates CNC linkage runs automatically.

2.Slender deep hole machining process without return, drilling efficiency is as high as 6 times more than ordinary drilling machine.

3.Processing aperture range, gun drill; ∮30-35 mm, BTA: ∮18-65(BTA is optional).

4.Unilateral processing depth of up to 2500 mm, length to diameter ratio of 100 or higher.

5.With the ideal size accuracy, hole drilling accuracy of straightness, and roughness.

Reviews

There are no reviews yet.