FEATURE

1.FANUC 0i –MF CNC system: stable performance, convenient operation programming, perfect and punctual after-sales service.

2.FANUC servo motor for six coordinate axis and main axis: good characteristic and perfect low speed performance.

3.With high-precision ball screw bar and rolling linear guide, the operating components make positioning accurately.

4.Remote control device is adopted in cooling system. Depends on the hole size, materials, chips and required precision, adjusting the flow rate and pressure can optimize the cooling result.

5.Precision detection: The dynamic inspection is done by British Renishaw laser interferometer. It makes compensation dynamically according to the test result, which ensures the positioning of the whole machine and re-positioning accurately.

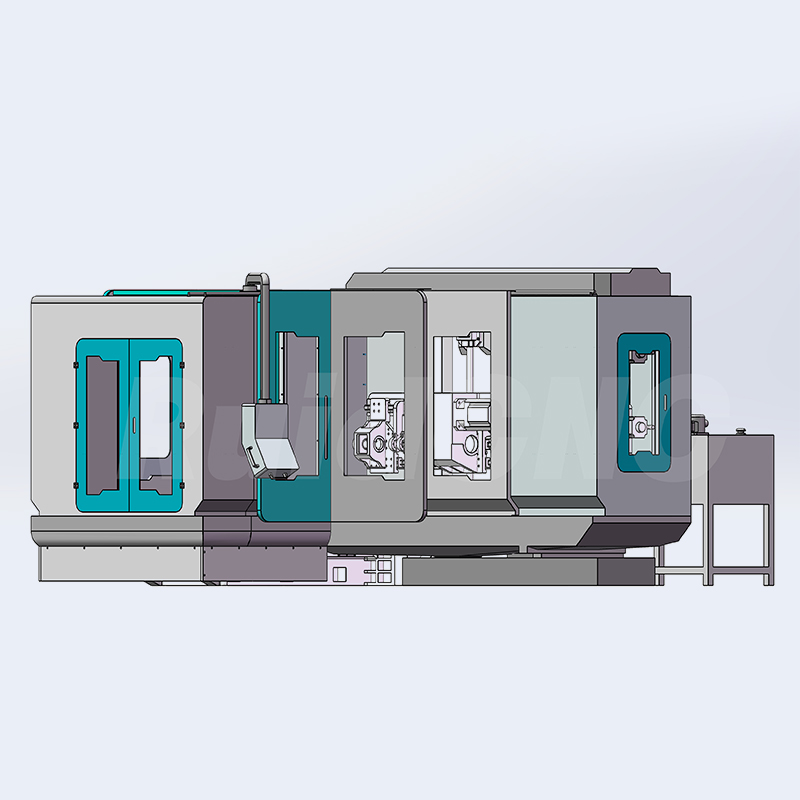

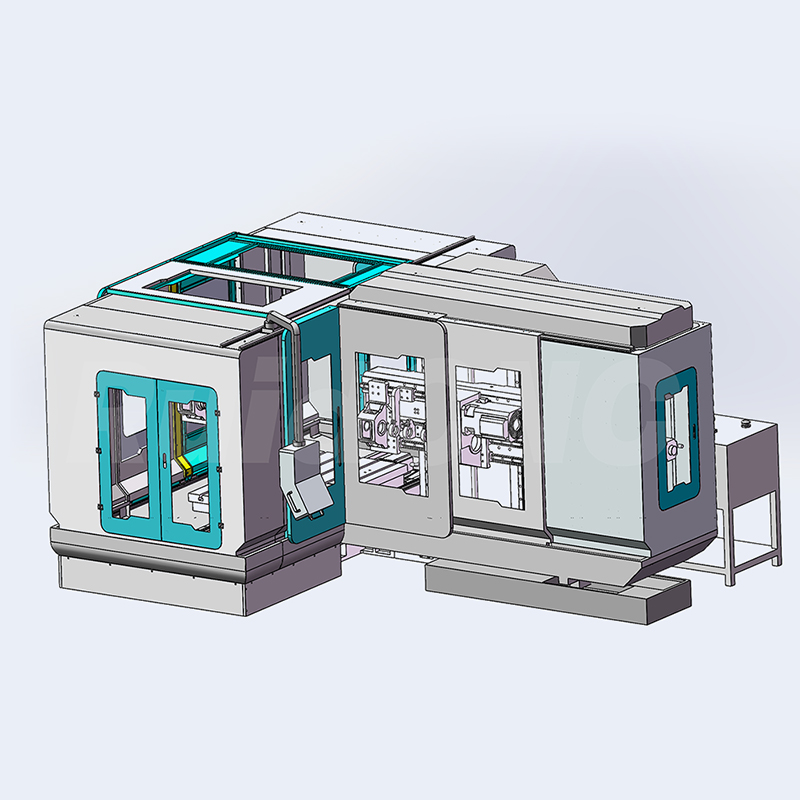

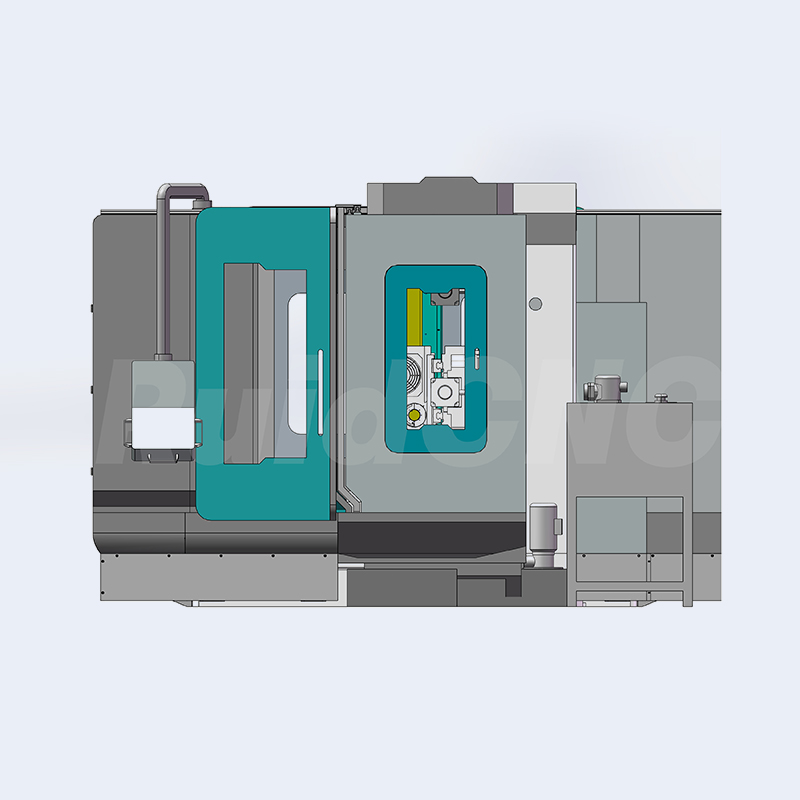

6.ZJR series CNC deep hole drilling machine is mainly used for extremely difficult processes of deep hole in mold industry. It’s spoken highly of its high-efficiency, low-cost, humanized technological process.

Reviews

There are no reviews yet.