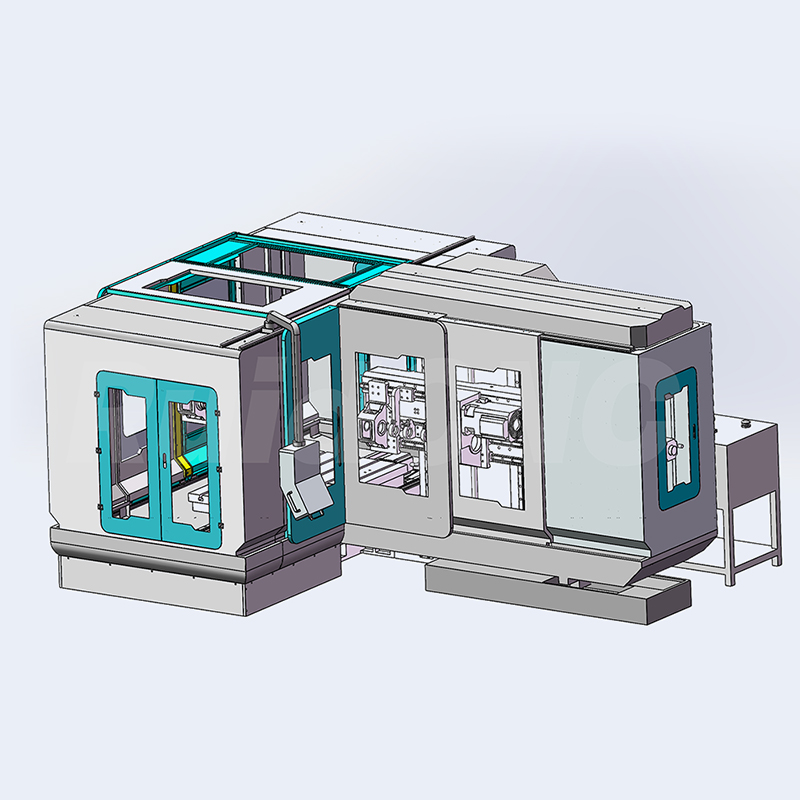

Deep Hole Drilling Machine – Precision Engineered for Excellence

RD1612-16H CNC

Powerful Deep Hole Drilling Performance

This deep hole drilling machine delivers fast, accurate results. Tough jobs become simple. Every hole meets top standards.

Built Strong for Demanding Jobs

Our deep hole drilling machine won’t vibrate. The solid frame keeps everything steady. Get perfect holes every time.

Smart 3-Axis CNC Control

Push buttons, get perfect holes. The system remembers your work. Same great results every run.

Advanced Gun Drilling Technology

Small holes or big – no problem. Tools stay sharp longer. Parts come out cleaner.

Automated Efficiency Features

- Coolant stays clean always

- Chips remove themselves

- Smart cooling protects parts

- Safety covers included

Why Professionals Choose Us

✔ Beats other machines

✔ Makes more parts faster

✔ Rarely needs stops

✔ Fits small spaces

Upgrade Your Manufacturing Today

Ditch old machines. Make more. Make better. Earn more.

Contact now – don’t miss out!

FEATURE

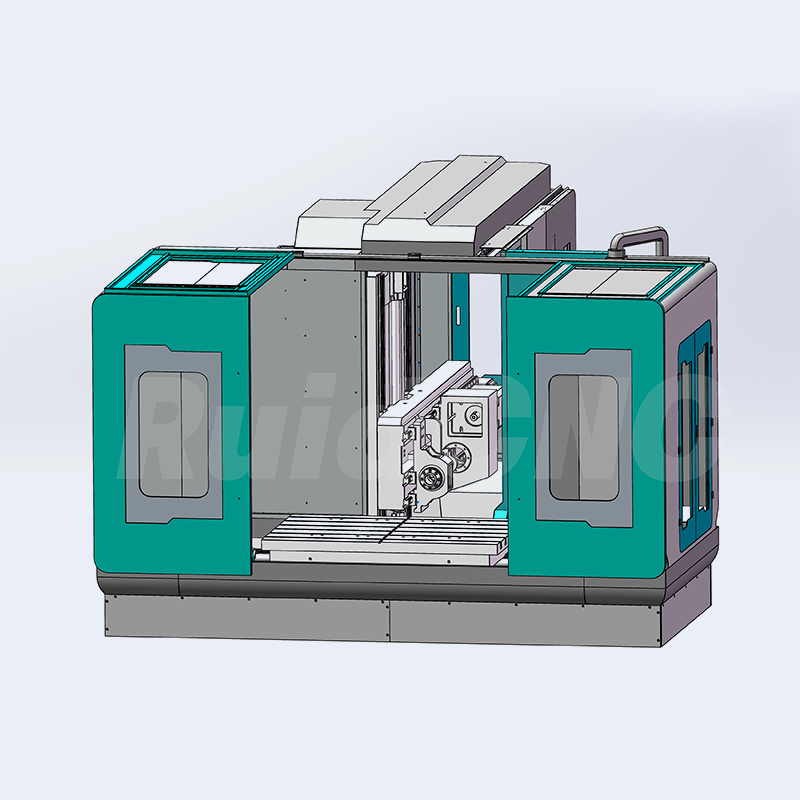

The RD-H three-axis horizontal CNC deep hole drilling machine offers the following advantages:

- High-strength cast iron bed and column, artificially aged to eliminate internal stress, ensuring excellent stability and reliability.

- Widened column structure design, with two precision heavy-duty linear guides, improving the stability of the drilling spindle carriage during machining. The column is equipped with an internal balance counterweight system, further enhancing carriage stability and reducing the risk of Y-axis screw overload.

- Efficient deep hole machiningvia X and Y axis adjustments for diverse part processing.

- Constant clamping devices on X and Y axes, locking during machining to significantly improve stability during large-diameter hole entry.

- Strong machining capability, with a maximum solid drilling diameter of 50mm(up to 60mmin special cases).

- Spindle collet: ER50 collet, capable of clamping up to ∅35mm, meeting the demands for large-diameter tool clamping and stronger holding force.

- Adjustable front guide, allowing precise correction of guidance and spindle concentricity, as well as facilitating maintenance.

- High-pressure oil supply systemwith full servo control; input the tool diameter, and the oil pressure adjusts automatically, simplifying operation and reducing errors. The pump uses a high-pressure internal gear pump, featuring high pressure, low noise, and long lifespan.

- Seven-stage filtration systemwith a cutting oil filtration precision of 30μm, protecting the high-pressure oil pump for long-term efficient operation and improving machining precision and surface finish.

- Compressor-type oil coolermaintains temperature within a set range, ensuring stable machining of parts over extended periods.

- CNC system: Taiwan’s New Generation 21MA-E CNC system, with optional Fanuc OiMF or Siemens 828D systems.

- Standard automatic magnetic chip conveyor, transporting iron chips to an external chip cart. Optional chain plate or screw-type chip conveyors are available.

- Reliable safety protective cover, aesthetically pleasing, convenient for loading/unloading, and preventing cutting oil splatter, making the machine safer and more environmentally friendly.

Reviews

There are no reviews yet.