ZJR series CNC deep hole drilling machine is automatic and multifunctional, majoring in deep hole drilling and cutting, while milling function is also professional. With the modern industry advance technology, the performance, accuracy, processing range, operating mode and working efficiency are in the international advanced level.

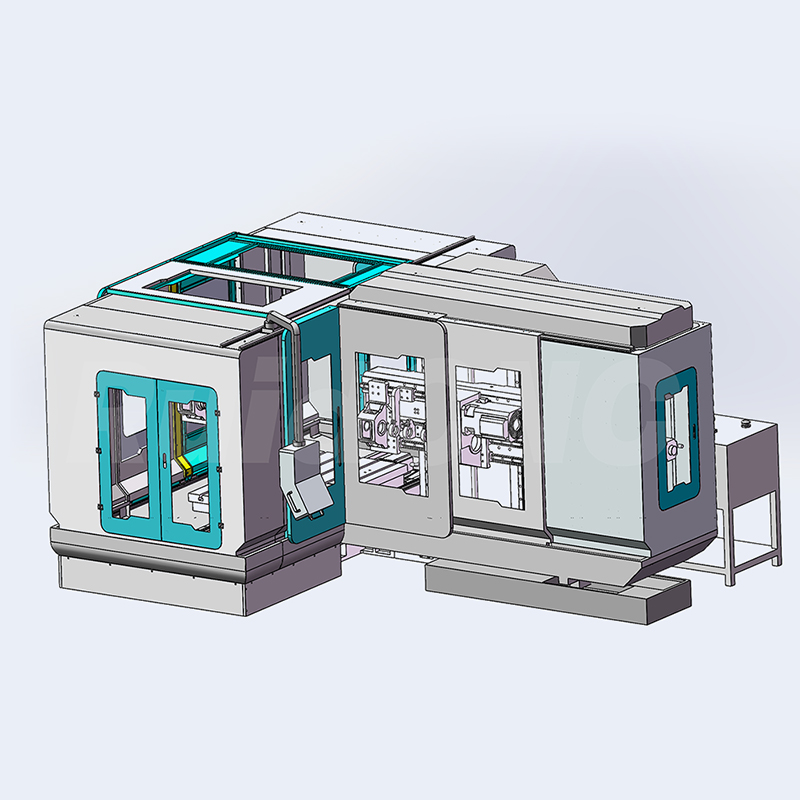

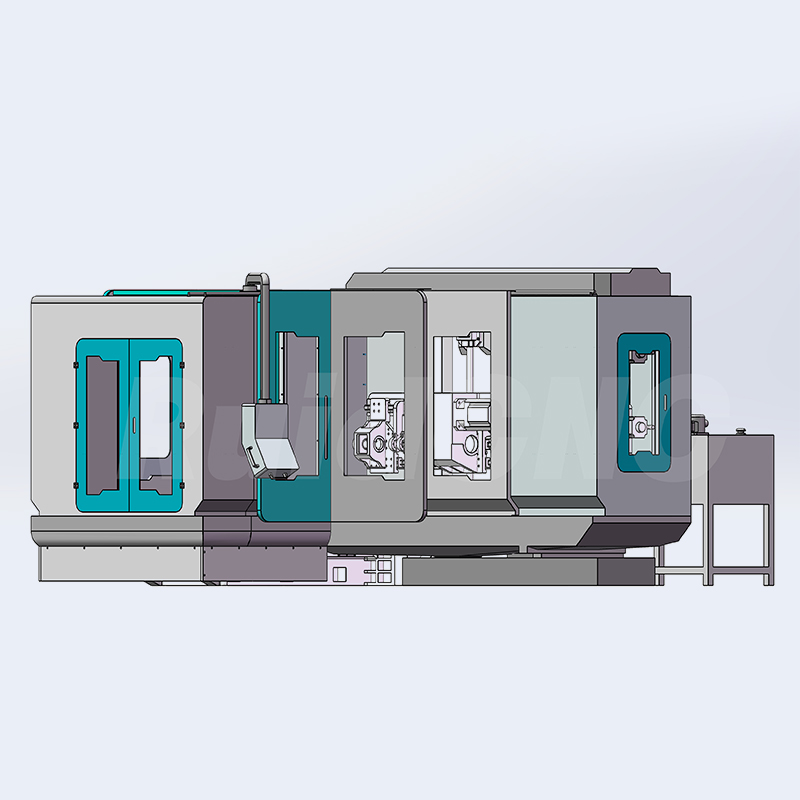

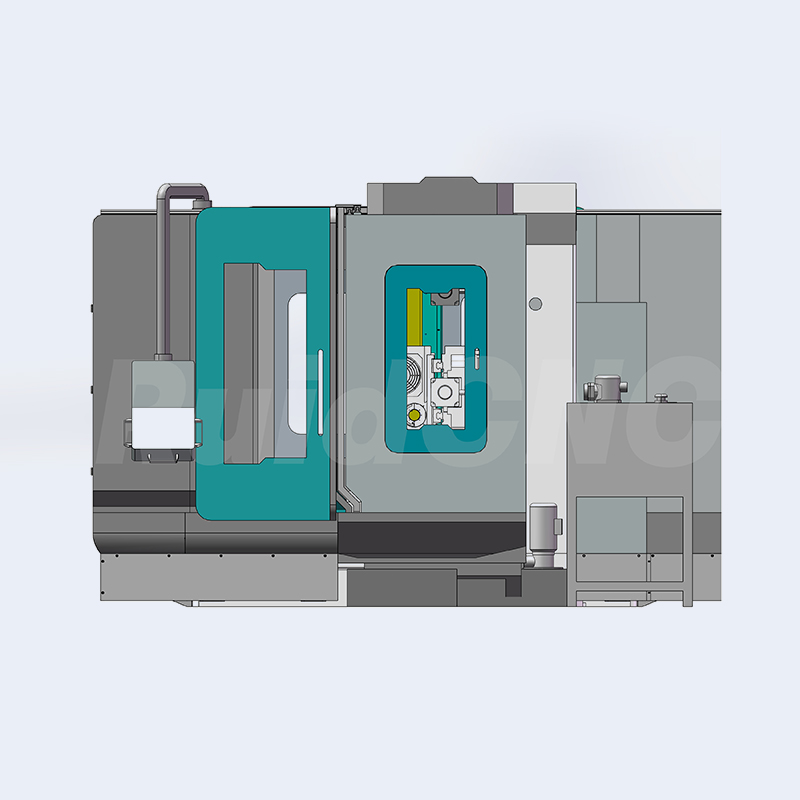

RD1210-10M Six Axis CNC Deep Hole Drilling Machine

ZJR series CNC deep hole drilling machine is automatic and multifunctional, majoring in deep hole drilling and cutting, while milling function is also professional. With the modern industry advance technology, the performance, accuracy, processing range, operating mode and working efficiency are in the international advanced level.

Download “ZJR10-1210 Six Axis CNC Deep Hole Drilling Machine” Shuangli-Deep-Hole-Drilling-Machine-Catelogue.pdf – Downloaded 23 times – 30.58 MB

FEATURE

1.FANUC 0i –MF CNC system: stable performance, convenient operation programming, perfect and punctual after-sales service.

2.FANUC servo motor for six coordinate axis and main axis: good characteristic and perfect low speed performance.

3.With high-precision ball screw bar and rolling linear guide, the operating components make positioning accurately.

4.Remote control device is adopted in cooling system. Depends on the hole size, materials, chips and required precision, adjusting the flow rate and pressure can optimize the cooling result.

5.Precision detection: The dynamic inspection is done by British Renishaw laser interferometer. It makes compensation dynamically according to the test result, which ensures the positioning of the whole machine and re-positioning accurately.

6.ZJR series CNC deep hole drilling machine is mainly used for extremely difficult processes of deep hole in mold industry. It’s spoken highly of its high-efficiency, low-cost, humanized technological process.

DATA SHEET

ltems | ZJR10-1210 | ||

Diameter of the Hole for Gun Drill | r3-30mm | ||

Maximum Depth of the Hole for Gun Drill | 1000 mm | ||

Processing Ranoa(from Left to Right) of the workingTable | 1200 mm | ||

Processing Range of sliding Table | 1000 mm | ||

Processing Range of Column | 500mm | ||

The Rotary Angla of Ram | The Spindle Turrs upward 15 degrees,and down to 25 degrees | ||

Taper Hole of Spindle | BT40 | ||

Maximum Speed of Spindle | 4500 mm | ||

Spindle Motor | 11kw | ||

X Axis Servo Motor | 27 N.m | ||

Y Axis Servo Motor | 27N.m | ||

Z Axis Servo Motor | 27N.m | ||

W Axis Servo Motor | 11 N.m | ||

A Axis Servo Motor | 20 N.m | ||

B Axis Servo Motor | 20N.m | ||

Total Power | 45 kw | ||

Max.Loading Capacity | 5 ton | ||

CONTACT NOW

Related products

- Six Axis Drilling

RD2315-15M Six Axis CNC Deep Hole Drilling Machine

- Six Axis Drilling

RD2515-15M Six Axis CNC Deep Hole Drilling Machine

- Six Axis Drilling

RD3017-15M Six Axis CNC Deep Hole Drilling Machine

Request a Quote

Ready to Work Together? Build a project with us!

Learn More From

Frequently Asked Questions

Clean the small and medium-sized drag plate guide rail surfaces and tailstock sleeve sliding surfaces of the CNC deep hole drilling and boring machine body; Clean the screw rod, smooth rod, and clutch lever; Clean the surfaces of motors, electrical boxes, belt covers, and other parts with dust and oil stains, and clean the cooling pump and its accessories; Check if the oil level in the headboard box has been filled to the oil level indicator position; Add lubricating oil to the oil nozzles and grooves on the guide rail surface, tailstock sleeve surface, and other parts, and add butter to the grease cup.

Deep hole drilling machine: a specialized machine tool equipped with a high-pressure cooling system and guiding device, suitable for high-precision deep hole machining.

CNC lathe/machining center: Install deep hole drilling accessories (such as BTA system, gun drilling system).

Regularly replace cutting fluid and clean the filtration system to prevent impurities from blocking the pipeline.

Check the fit clearance between the guide sleeve and the drill bit (usually 0.01~0.03mm), and replace it promptly after wear.

After use, the cutting tools need to be cleaned, coated with anti rust oil, and stored in a dry environment.

Reviews

There are no reviews yet.