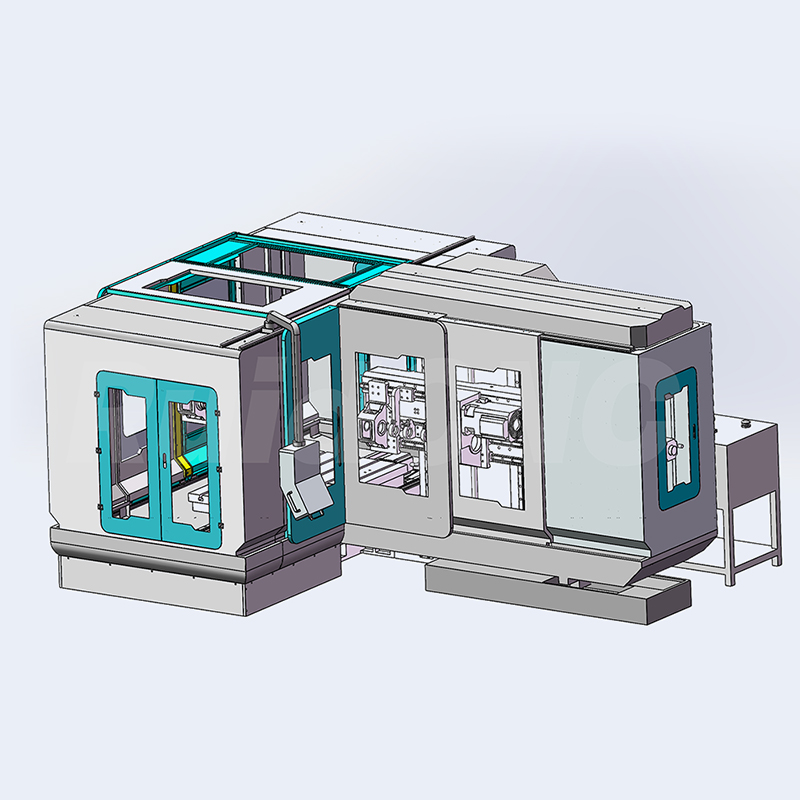

Engineered for Precision & Durability

Premium Material Selection

HT300 High-Strength Cast Iron: Combines exceptional vibration damping (damping coefficient ≥0.03) with robust tensile strength (≥300 MPa).

Microstructural Integrity: Rigorously validated under ISO 185 standards to ensure dense graphite morphology and zero shrinkage porosity.

Advanced Process Assurance

Stress Elimination: Multi-stage stress relief (annealing, high-frequency oscillation, natural aging) removes >99% residual stress.

Stable Microstructure: Precision-controlled cooling rates and alloying elements (Cu, Sn) refine grain structure for uniform mechanical properties.

Built to Last in Extreme Conditions

Multi-Layer Protective Coating: Anti-impact, corrosion-resistant, and anti-rust composite spraying technology guarantees longevity in harsh industrial environments.

Advanced Process Assurance

Reinforced “工”-Beam Ribs: Longitudinal ribs maximize bending rigidity and load-bearing capacity for heavy-duty operations.

Honeycomb Cross-Ribs: Lightweight transverse design shifts resonance frequency beyond 200 Hz, effectively minimizing vibration-induced deformation.

Ultra-Precision Machine Bed

Critical Surface Finishing: Guideway mounts, screw holes, and locating holes undergo precision grinding, scraping, and milling to achieve micron-level flatness.

Seamless Assembly: Reference planes and alignment pins ensure stress-free assembly and geometric accuracy across the entire machine tool.

Why Choose Our Deep Hole Drilling Solutions?

HT300 Material: Unmatched stability for precision machining.

ISO 185-Certified: Guaranteed microstructural quality.

Resonance Control: Patented honeycomb ribs for vibration-freeperformance.

Industrial-Grade Protection: Engineered to thrive in demanding conditions.

Key Specifications

• Damping Coefficient: ≥0.03

• Tensile Strength: ≥300 MPa

• Resonance Frequency: >200 Hz

• Flatness Tolerance: Micron-level

Reviews

There are no reviews yet.