FEATURE

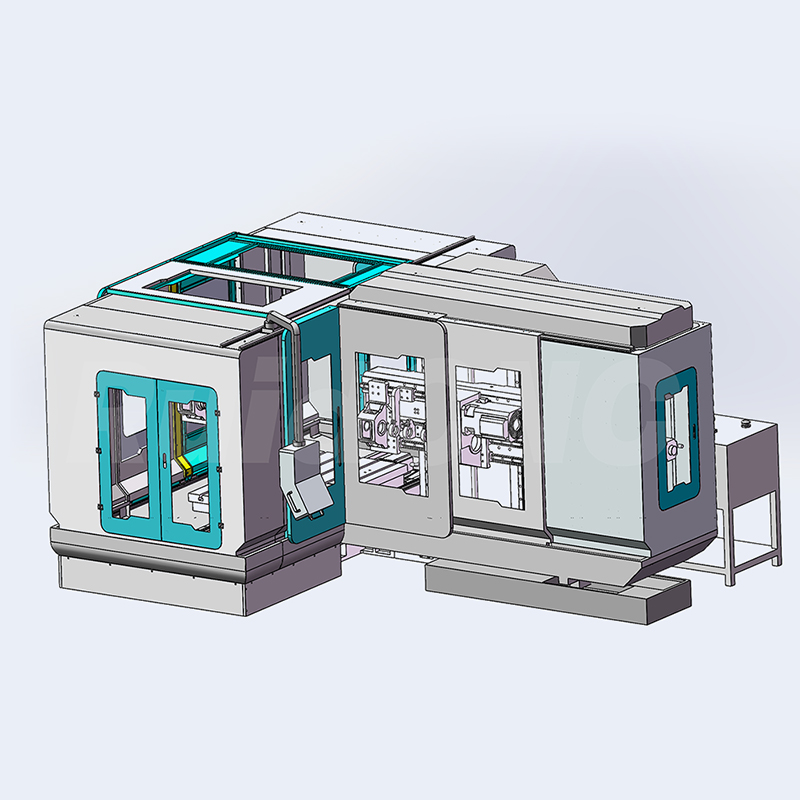

1.There are both single axis processing and multiple axis processing function.

2.The CNC programming automatic processing ensures the good quality such as the spacing of the hole, diameter tolerance, verticality, harshness, etc.

3.It’s a totally different from the traditional processing ways of multiple collections, which extremely improves the production capacity.

4.There are also optional chip conveyors: outside chip conveyor gun drill or inner chip conveyor BTA.

Reviews

There are no reviews yet.