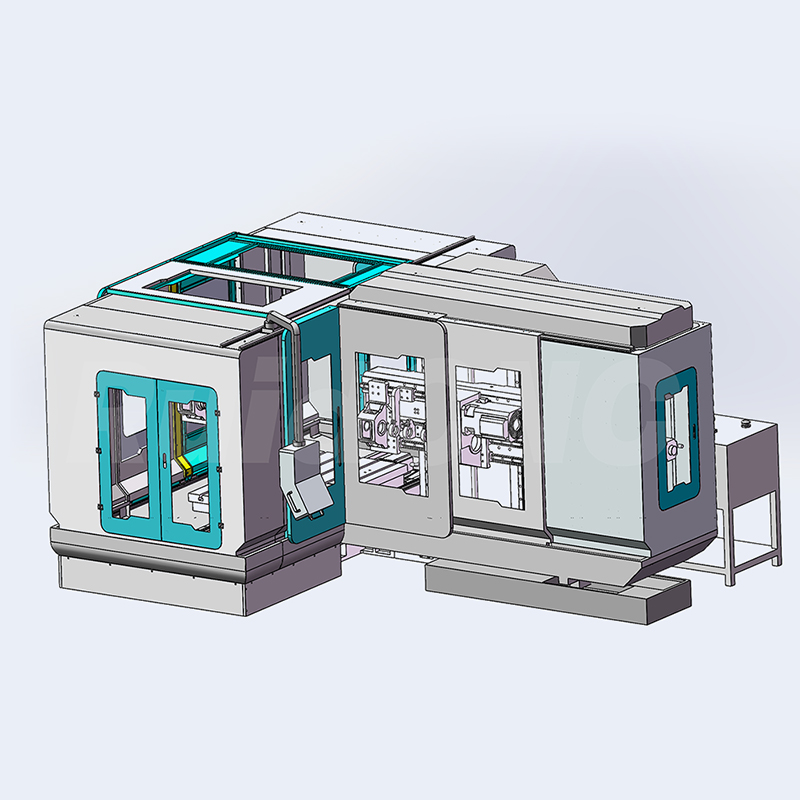

The RD-H CNC deep hole drilling machine is a three-axis CNC gun drilling machine designed for deep hole machining of box-type parts, special-shaped components, or plastic molds. It features high flexibility, high efficiency, high precision, and high automation. A single clamping allows for deep hole machining at multiple positions.

The machine mainly consists of a column, deep hole drilling spindle system, bed, worktable, high-pressure cooling filtration system, chip conveyor chain, oil cooler, electrical and CNC systems, and machine tool protective cover. The worktable moves along the X-axis on the bed, the spindle system moves up and down along the Y-axis of the column, and the Z-axis realizes spindle feed and retraction. The movement of the X, Y, and Z axes is driven by the CNC system, servo motors, guide rails, and ball screws.

This machine adopts gun drilling technology, with a solid drilling diameter range of C3mm–C50mm. During processing, the workpiece is fixed on the worktable, and the tool rotates and feeds. By adjusting the X and Y axes, the machining position of the holes can be changed, enabling efficient three-axis deep hole machining for various parts.

FEATURE

The RD-H three-axis horizontal CNC deep hole drilling machine offers the following advantages:

- High-strength cast iron bed and column, artificially aged to eliminate internal stress, ensuring excellent stability and reliability.

- Widened column structure design, with two precision heavy-duty linear guides, improving the stability of the drilling spindle carriage during machining. The column is equipped with an internal balance counterweight system, further enhancing carriage stability and reducing the risk of Y-axis screw overload.

- Efficient deep hole machiningvia X and Y axis adjustments for diverse part processing.

- Constant clamping devices on X and Y axes, locking during machining to significantly improve stability during large-diameter hole entry.

- Strong machining capability, with a maximum solid drilling diameter of 50mm(up to 60mmin special cases).

- Spindle collet: ER50 collet, capable of clamping up to ∅35mm, meeting the demands for large-diameter tool clamping and stronger holding force.

- Adjustable front guide, allowing precise correction of guidance and spindle concentricity, as well as facilitating maintenance.

- High-pressure oil supply systemwith full servo control; input the tool diameter, and the oil pressure adjusts automatically, simplifying operation and reducing errors. The pump uses a high-pressure internal gear pump, featuring high pressure, low noise, and long lifespan.

- Seven-stage filtration systemwith a cutting oil filtration precision of 30μm, protecting the high-pressure oil pump for long-term efficient operation and improving machining precision and surface finish.

- Compressor-type oil coolermaintains temperature within a set range, ensuring stable machining of parts over extended periods.

- CNC system: Taiwan’s New Generation 21MA-E CNC system, with optional Fanuc OiMF or Siemens 828D systems.

- Standard automatic magnetic chip conveyor, transporting iron chips to an external chip cart. Optional chain plate or screw-type chip conveyors are available.

- Reliable safety protective cover, aesthetically pleasing, convenient for loading/unloading, and preventing cutting oil splatter, making the machine safer and more environmentally friendly.

Reviews

There are no reviews yet.